Start your trial.į), on average you'll feel fine (8.

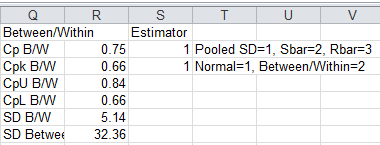

This template for Excel calculates Cp, Cpk, Pp, and Ppk for up to 8 characteristics and 100 measurements when you just drop in your data. With 1factory, you can speed-up QC tasks and ensure quality at source, within. The Money Market Hedge: How It Works 1factory simplifies the collection, analysis, and reporting of quality control data.

CPK CALCULATIONS IN EXCEL FREE SOFTWARE PROFESSIONAL

A Quality Professional returning to the industry to contribute to the Business Excellence Journey of the organization after a consulting stint. Read about non-normal distributions in the real world at our Knowledge Center today! Statistical Process Control (SPC) Introduction and Background MoreSteam Hint: As a pre-requisite to improve your understanding of the following content, we recommend. Quality America is your online source for all things Lean Six Sigma. Quality & Productivity Solutions (QPS) is an accredited organization offering all documentation consulting, implementation, training and auditing for all Management. Work on RasMol 2.7.5 supported in part by grant. Warning: Invalid argument supplied for foreach() in /srv/users/serverpilot/apps/jujaitaly/public/index.php on line 447.

F) and one foot in a bucket of scalding water (1. Consider two examples: If you put one foot in a bucket of ice water (3. Why Is Dispersion So Important? Often we focus on average values, but understanding dispersion is critical to the management of industrial processes. The standard deviation can be easily calculated from a group of numbers using many calculators, or a spreadsheet or statistics program. This can be expressed by the range (highest less lowest), but is better captured by the standard deviation (sigma). If you have reviewed the discussion of frequency distributions in the Histogram module, you will recall that many histograms will approximate a Normal Distribution, as shown below (please note that control charts do not require normally distributed data in order to work - they will work with any process distribution - we use a normal distribution in this example for ease of representation): In order to work with any distribution, it is important to have a measure of the data dispersion, or spread. This tutorial provides a brief conceptual background to the practice of SPC, as well as the necessary formulas and techniques to apply it. Shewhart devised control charts used to plot data over time and identify both Common Cause variation and Special Cause variation. Based on experience with many types of process data, and supported by the laws of statistics and probability, Dr. Deming relabeled chance variation as Common Cause variation, and assignable variation as Special Cause variation. Shewhart identified two sources of process variation: Chance variation that is inherent in process, and stable over time, and Assignable, or Uncontrolled variation, which is unstable over time - the result of specific events outside the system. Edwards Deming, who introduced SPC to Japanese industry after WWII.Īfter early successful adoption by Japanese firms, Statistical Process Control has now been incorporated by organizations around the world as a primary tool to improve product quality by reducing process variation. Walter Shewhart of Bell Laboratories in the 1. Steam Hint: As a pre- requisite to improve your understanding of the following content, we recommend that you review the Histogram module and its discussion of frequency distributions.

Statistical Process Control (SPC) Tutorial.

0 kommentar(er)

0 kommentar(er)